Understanding Ultrasonic Clamp-On Flow Meters

⬅ Back to Posts

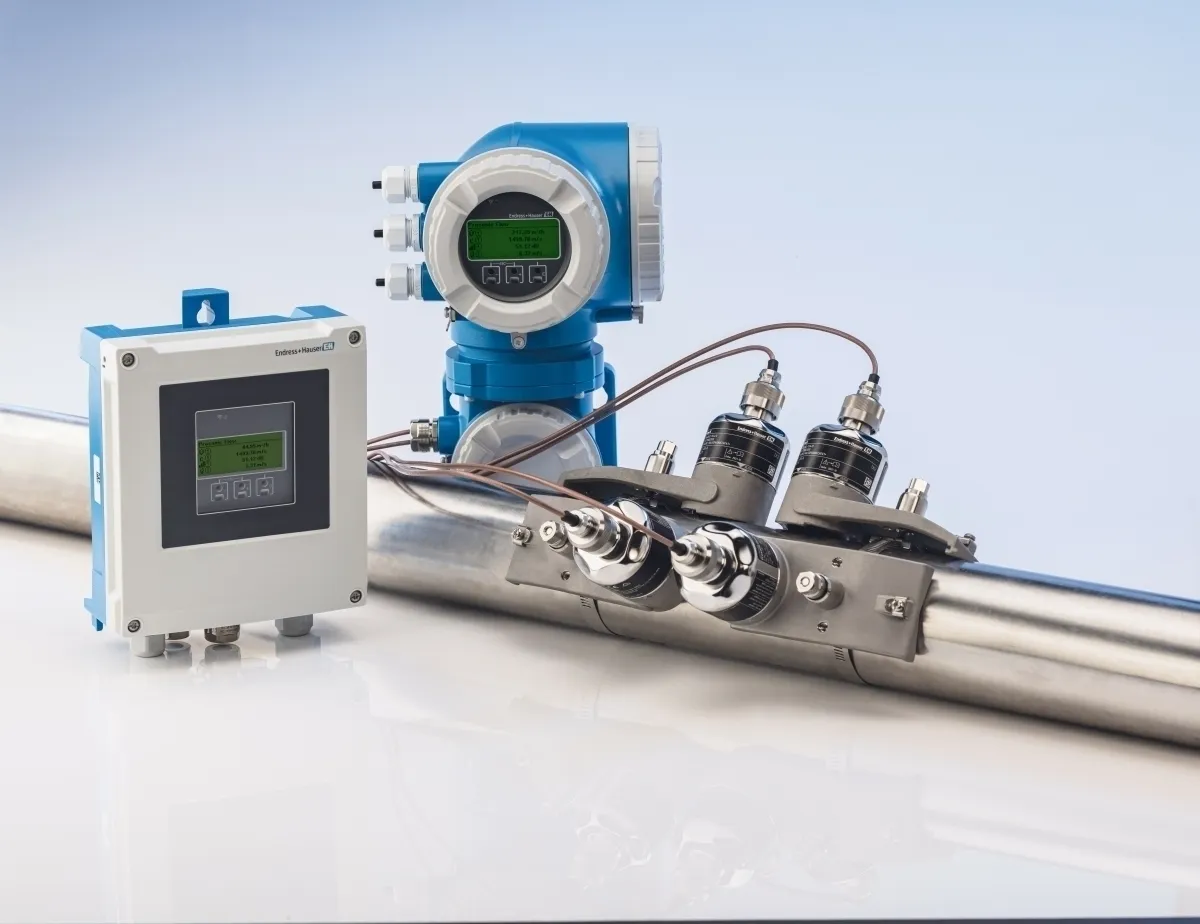

Ultrasonic clamp-on flow meters are non-invasive devices used to measure the flow rate of fluids in pipes. They are highly valued in industries such as water treatment, HVAC, oil and gas, and chemical processing, where accurate, non-intrusive flow measurement is crucial for process control and efficiency.

How Ultrasonic Clamp-On Flow Meters Work

Ultrasonic clamp-on flow meters operate using the principle of transit-time measurement. The meter consists of two or more ultrasonic transducers that are clamped onto the exterior of a pipe. These transducers emit and receive ultrasonic signals that travel through the pipe walls and the fluid inside. The key concept is the difference in transit time between ultrasonic signals traveling with the flow (downstream) and against the flow (upstream). When fluid is flowing, the downstream signal travels faster than the upstream signal, and this time difference is proportional to the flow rate.

The flow meter calculates the flow rate by analyzing this time difference, taking into account the pipe dimensions and the speed of sound in the fluid. Some models also use the Doppler effect, where the frequency shift of the reflected ultrasonic waves is used to measure flow, particularly in cases where the fluid contains suspended particles or bubbles.

Key Advantages

Non-Invasive Installation: One of the primary advantages of ultrasonic clamp-on flow meters is that they do not require any physical penetration of the pipe. The transducers are simply clamped onto the exterior, making installation quick, easy, and cost-effective. This non-invasive nature eliminates the risk of leaks and contamination, which is especially important in hygienic or hazardous environments.

Versatility: Ultrasonic clamp-on meters can be used on a wide range of pipe materials and sizes, from metal to plastic, and for different types of fluids, including water, chemicals, oils, and even some gases. This versatility makes them suitable for various industrial applications.

Maintenance-Free: Since there are no moving parts or components in contact with the fluid, ultrasonic flow meters are generally maintenance-free. This leads to lower operational costs and reduced downtime.

Portability: Many ultrasonic clamp-on flow meters are designed to be portable, allowing for spot checks and temporary measurements in different locations without the need for permanent installation.

Applications

Water Treatment: Ultrasonic clamp-on meters are used to monitor water flow in treatment plants, distribution networks, and irrigation systems, ensuring efficient water management.

HVAC Systems: They are used to measure the flow of heating and cooling fluids in HVAC systems, optimising energy use and system performance.

Oil and Gas: In the oil and gas industry, these meters measure the flow of crude oil, refined products, and other fluids, helping to manage resources and ensure process safety.

Chemical Processing: They provide accurate flow measurement for various chemicals, ensuring precise dosing and mixing in industrial processes.

Challenges and Considerations

While ultrasonic clamp-on flow meters offer many benefits, their performance can be influenced by several factors. The accuracy of the measurement can be affected by the pipe material, fluid properties, and installation conditions. For example, pipes with thick walls or made from certain materials might attenuate the ultrasonic signal, reducing accuracy. Additionally, fluids with high levels of suspended solids or air bubbles might require specific models designed to handle such conditions.

Ultrasonic clamp-on flow meters are an excellent choice for non-invasive flow measurement in a wide range of applications. Their ease of installation, versatility, and maintenance-free operation make them a valuable tool for industries requiring reliable and accurate flow measurement without interrupting the flow or compromising the integrity of the piping system. Proper selection based on the specific application and careful installation are key to maximising their performance.