Understanding Turbine Flow Meters

⬅ Back to Posts

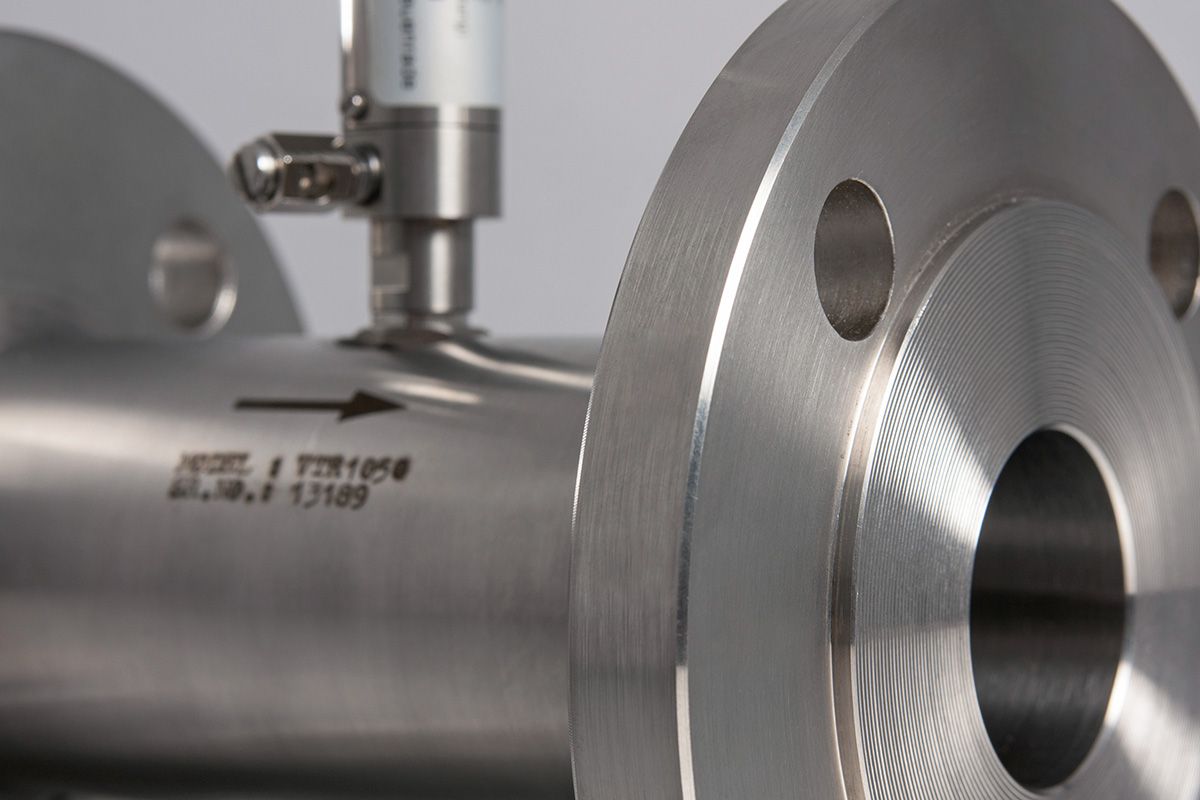

Turbine flow meters are precision instruments used to measure the flow rate of liquids and gases. They are widely utilized in industries such as oil and gas, water treatment, chemical processing, and aviation due to their high accuracy, repeatability, and reliability. Turbine flow meters are ideal for applications where precise flow measurement is critical for process control, resource management, and ensuring the quality of end products.

How Turbine Flow Meters Work

Turbine flow meters operate based on the principle of angular momentum. The core component of the meter is a multi-bladed rotor (or turbine) that is positioned in the path of the fluid flow. As the fluid flows through the meter, it strikes the blades of the rotor, causing it to spin. The speed at which the rotor spins is directly proportional to the flow rate of the fluid.

Magnets or optical sensors are positioned near the rotor to detect its rotation. Each rotation or a fraction of a rotation generates an electrical pulse. The frequency of these pulses is proportional to the flow velocity of the fluid. By calibrating the meter with the fluid's known properties, the volumetric flow rate can be accurately calculated from the pulse frequency.

Key Advantages

High Accuracy and Repeatability: Turbine flow meters are known for their high accuracy, typically within ±0.5% to ±1% of the measured value, making them suitable for applications requiring precise flow measurement. They also offer excellent repeatability, ensuring consistent performance over time.

Wide Range of Applications: These meters can measure a broad range of fluid viscosities and flow rates, making them versatile across various industries. They are commonly used for both liquid and gas applications.

Low Pressure Drop: Turbine flow meters generally cause minimal pressure drop in the flow system, meaning they do not significantly affect the fluid's pressure or flow characteristics, making them suitable for low-pressure applications.

Compact and Robust Design: Turbine flow meters are relatively compact and durable, able to withstand harsh operating conditions, including high pressure and temperature, which makes them suitable for demanding industrial environments.

Applications

Oil and Gas Industry: Turbine flow meters are used to measure the flow of hydrocarbons, such as crude oil and natural gas, during extraction, processing, and distribution. Their accuracy and reliability are crucial for custody transfer and regulatory compliance.

Water Treatment and Distribution: These meters are employed to monitor water flow in treatment plants and distribution networks, ensuring efficient water management and leak detection.

Chemical Processing: In chemical plants, turbine flow meters measure the flow of various liquids and gases, ensuring precise dosing, mixing, and reaction control.

Aviation: Turbine flow meters are used to measure the flow of aviation fuels and hydraulic fluids, ensuring safe and efficient operation of aircraft.

Challenges and Considerations

While turbine flow meters offer many benefits, there are some challenges to consider. They are sensitive to fluid properties, such as viscosity, temperature, and the presence of particulates or entrained air, which can affect measurement accuracy. Fluids with high viscosity or those containing solid particles can cause wear and tear on the turbine blades, leading to decreased performance and increased maintenance requirements. Additionally, turbine flow meters require a well-developed flow profile, typically requiring straight pipe runs upstream and downstream to ensure accurate readings.

Turbine flow meters are a highly accurate and reliable solution for measuring fluid flow in a variety of industrial applications. Their high precision, repeatability, and versatility make them ideal for industries where exact flow measurement is crucial. However, proper selection, installation, and maintenance are key to ensuring optimal performance, especially in environments where fluid properties and operating conditions can pose challenges.