Unlocking the Flow: Understanding Electromagnetic Flow MetersHello world!

⬅ Back to Posts

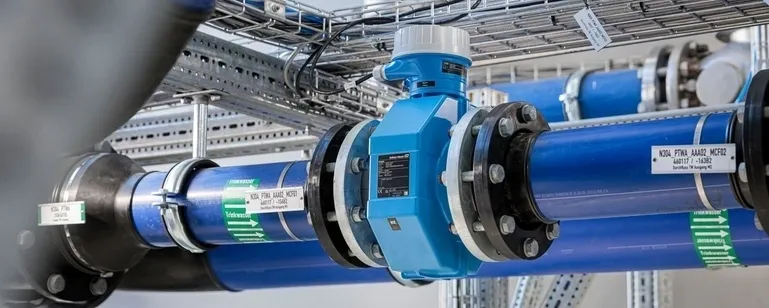

In the world of industrial fluid measurement, precision is paramount. Accurate flow measurement ensures efficient process control, resource management, and cost savings. Among the various technologies available, electromagnetic flow meters, often referred to as mag meters, stand out for their reliability and precision in measuring the flow of conductive liquids. In this blog post, we will delve into the mechanics, benefits, and applications of electromagnetic flow meters, shedding light on why they are a popular choice in many industries.

What is an Electromagnetic Flow Meter?

An electromagnetic flow meter is a device that measures the flow rate of a fluid by using Faraday's Law of Electromagnetic Induction. According to this principle, when a conductive fluid flows through a magnetic field, it induces a voltage proportional to the velocity of the fluid. This induced voltage is then measured by electrodes positioned perpendicular to the flow and magnetic field, providing a direct measure of the flow rate.

How Do Electromagnetic Flow Meters Work?

The operation of an electromagnetic flow meter involves several key components:

- Flow Tube: The fluid passes through a non-conductive, often ceramic or plastic-lined, flow tube.

- Magnetic Field Coils: These coils generate a magnetic field across the flow tube.

- Electrodes: Positioned on the sides of the flow tube, electrodes detect the induced voltage as the conductive fluid moves through the magnetic field.

- Signal Converter: This component processes the voltage signal and converts it into a readable flow rate.

The relationship between the flow velocity (v), magnetic field strength (B), and induced voltage (E) can be described by the formula: E = B * L * v, where L is the distance between the electrodes. The signal converter uses this relationship to calculate the flow rate accurately.

Advantages of Electromagnetic Flow Meters

Electromagnetic flow meters offer several benefits that make them a preferred choice in various industries:

- High Accuracy: Mag meters provide highly accurate flow measurements, often within ±0.2% of the actual flow rate.

- No Moving Parts: The absence of moving parts reduces wear and tear, leading to lower maintenance requirements and longer service life.

- Wide Range of Sizes: They are available in sizes ranging from a few millimeters to several meters, accommodating different application needs.

- Versatility: Suitable for a wide range of conductive fluids, including slurries, corrosive liquids, and wastewater.

- Bidirectional Measurement: Capable of measuring flow in both directions, enhancing their versatility.

- Low Pressure Drop: The unobstructed flow path minimizes pressure loss, improving overall system efficiency.

Applications of Electromagnetic Flow Meters

Electromagnetic flow meters find applications across various industries due to their versatility and reliability:

- Water and Wastewater Management: Used extensively in municipal water supply systems, wastewater treatment plants, and irrigation systems for accurate water usage monitoring and leakage detection.

- Chemical Industry: Ideal for measuring corrosive and abrasive fluids, ensuring precise dosing and chemical process control.

- Food and Beverage Industry: Ensures sanitary conditions and accurate measurement of ingredients in production processes.

- Pulp and Paper Industry: Handles the challenging measurement of pulp slurries and other viscous fluids.

- Pharmaceutical Industry: Provides precise measurement necessary for the formulation of drugs and other products.

- Mining and Mineral Processing: Used for slurry measurement and other challenging applications.

Conclusion

Electromagnetic flow meters have revolutionized fluid flow measurement with their accuracy, durability, and versatility. Their ability to handle a wide range of conductive fluids without significant pressure loss or maintenance needs makes them indispensable in many industrial processes. As technology continues to advance, mag meters are likely to become even more efficient, further cementing their role as a critical tool in fluid measurement.

Whether you're managing a municipal water supply, overseeing chemical production, or ensuring the precise mixing of ingredients in food processing, electromagnetic flow meters offer a reliable solution for your flow measurement needs. Understanding their operation and benefits can help you make informed decisions to optimize your processes and improve overall efficiency.