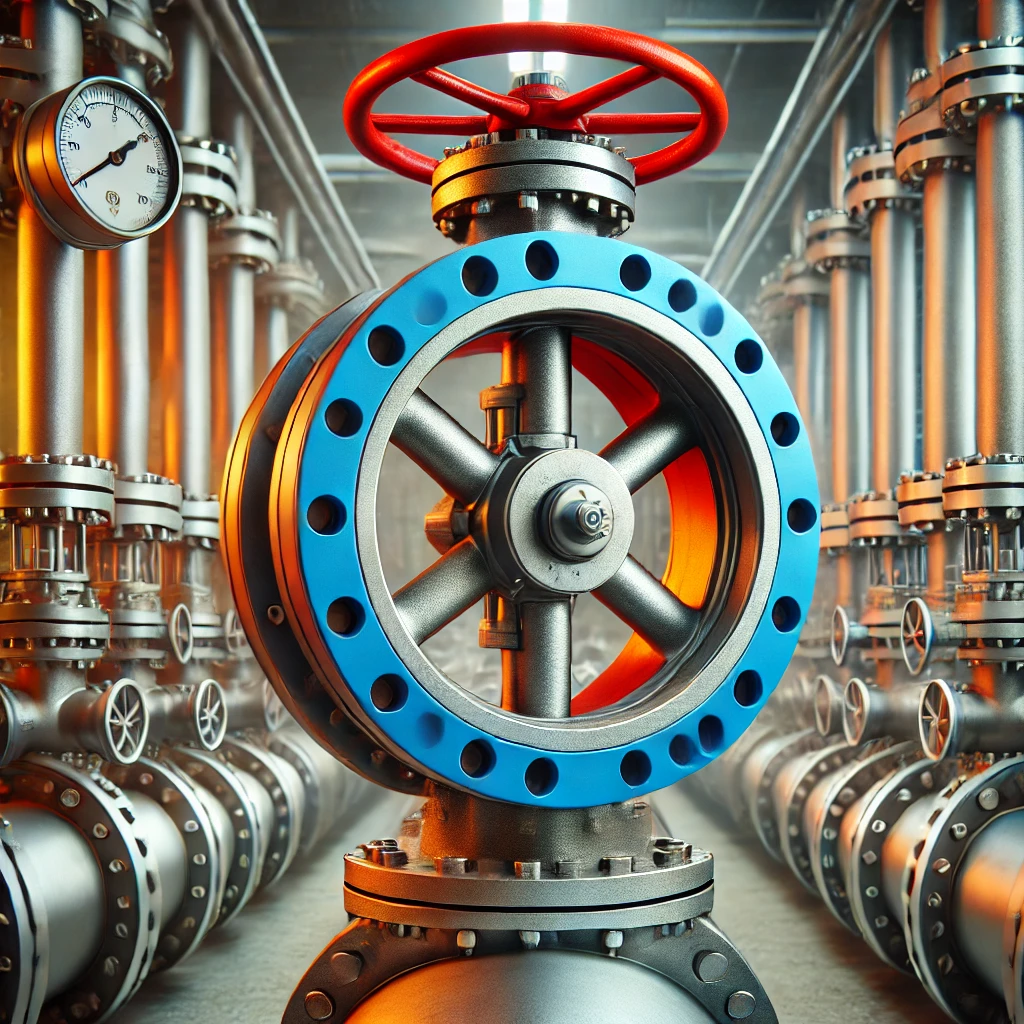

Butterfly Valves: Versatile and Efficient Flow Control Solutions

⬅ Back to Posts

Butterfly valves are a popular choice for controlling flow in piping systems, offering a compact and lightweight design, quick operation, and cost-effective performance. These versatile valves are widely used across industries for regulating fluids, gases, and even semi-solid substances.

What is a Butterfly Valve?

A butterfly valve is a quarter-turn valve that regulates the flow of fluid through a pipe by means of a rotating disc. This disc acts as the flow-controlling element and is positioned in the center of the pipe. When the valve is closed, the disc blocks the passage of fluid, and when open, it rotates to allow flow.

How Do Butterfly Valves Work?

- Disc and Stem Mechanism: The valve's disc is mounted on a rotating stem. When the stem turns, the disc pivots to either restrict or allow fluid flow.

- Quarter-Turn Operation: A 90-degree turn is sufficient to switch the valve between fully open and fully closed positions, enabling fast operation.

- Sealing: Depending on the valve type, elastomeric seals or metal seats ensure a tight shutoff, minimizing leaks.

Types of Butterfly Valves

Butterfly valves come in several designs, each suited to specific applications:

- Concentric Butterfly Valves: Feature a rubber-lined seat and a centered disc, ideal for low-pressure systems.

- Double-Eccentric (High-Performance) Butterfly Valves: The disc is offset from the valve seat, reducing wear and offering better sealing under higher pressures.

- Triple-Eccentric (Metal Seated) Butterfly Valves: Provide tight shutoff in extreme conditions, including high-pressure and high-temperature environments.

Applications of Butterfly Valves

Butterfly valves are used in various sectors due to their adaptability, such as:

- Water and Wastewater Management: For controlling water flow in treatment plants and distribution systems.

- Oil and Gas: In pipelines for crude oil, natural gas, and refined products.

- Power Generation: To manage cooling water and other utility systems.

- HVAC Systems: For regulating air flow in heating, ventilation, and air conditioning.

- Food and Beverage: In hygienic applications, such as beverage production lines.

Advantages of Butterfly Valves

- Compact Design: Requires less space compared to other valve types, making it ideal for confined installations.

- Lightweight: The simple construction reduces weight and installation costs.

- Cost-Effective: Offers reliable performance at a lower price point.

- Quick Operation: Allows rapid flow control with minimal effort.

- Low Maintenance: Fewer moving parts result in reduced maintenance requirements.

Limitations of Butterfly Valves

Despite their benefits, butterfly valves may have some drawbacks:

- Throttling Limitations: Not always suitable for precise flow control in certain applications.

- Pressure Drop: The disc remains in the flow path even when fully open, causing some resistance.

- Material Constraints: Not ideal for handling highly abrasive or corrosive media unless specially designed.

Selecting the Right Butterfly Valve

When choosing a butterfly valve, consider the following factors:

- Size and Pressure Rating: Ensure the valve matches the system’s specifications.

- Material Compatibility: Select materials that withstand the fluid’s properties and operating environment.

- Seal Type: Determine the required level of tightness based on application needs.

- Operational Requirements: Consider manual, electric, or pneumatic actuators for valve operation.

Maintenance Tips for Butterfly Valves

To maximize the lifespan of a butterfly valve:

- Inspect Regularly: Check for wear and tear on the disc, stem, and seals.

- Clean Periodically: Remove debris or buildup that could impair operation.

- Test Functionality: Operate the valve periodically to ensure smooth movement.

- Replace Worn Parts: Address damaged components promptly to prevent system failure.

Conclusion

Butterfly valves are an essential component in fluid control systems, offering versatility, efficiency, and reliability. Their wide range of applications and cost-effective nature make them a go-to choice for industries worldwide. Whether managing water flow in municipal systems or regulating gases in industrial processes, butterfly valves provide an optimal solution for efficient flow control.