The Future of Water Quality Monitoring with Intelligent Conductivity Sensors

⬅ Back to Posts

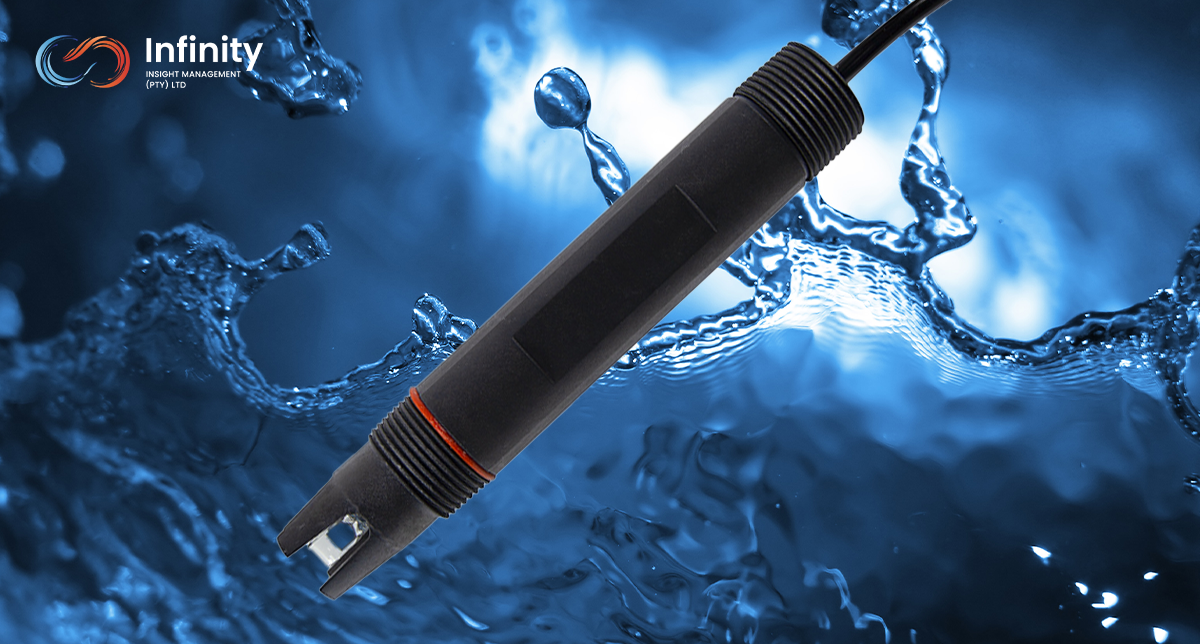

In industries where water quality plays a crucial role—such as wastewater treatment, chemical processing, food and beverage production, and pharmaceuticals—accurate and reliable monitoring of conductivity is essential. Conductivity sensors measure a liquid’s ability to conduct electricity. This provides key insights into purity, contamination levels, and overall composition. However, traditional conductivity sensors often require frequent calibration, manual data collection, and maintenance. Enter the Intelligent Conductivity Sensor, a game-changer in modern water quality management.

What is an Intelligent Conductivity Sensor?

An intelligent conductivity sensor is an advanced measuring device equipped with digital capabilities, self-diagnosing features, and remote communication functions. Unlike conventional sensors, these smart devices integrate advanced electronics and software to enhance accuracy, efficiency and ease of use.

Key Features and Benefits

- High Precision and Accuracy Intelligent conductivity sensors leverage digital signal processing (DSP) technology to provide precise and consistent readings. This minimizes errors caused by temperature fluctuations and external interferences.

- Automatic Temperature Compensation (ATC)Water conductivity is highly temperature-dependent. Intelligent sensors come with ATC to adjust readings accordingly, ensuring reliable results in varying environmental conditions.

- Real-time Monitoring and Data Logging Equipped with built-in memory and connectivity options (such as Modbus, RS485, or Bluetooth), these sensors continuously record and transmit data. This allows for remote analysis and process optimization.

- Self-Diagnosis and Predictive Maintenance Advanced self-diagnostic functions alert users to calibration needs, electrode fouling, or potential sensor failures. This reduces downtime and maintenance costs.

- Seamless Integration with Industrial Systems Designed for compatibility with SCADA (Supervisory Control and Data Acquisition) and IoT platforms, intelligent conductivity sensors enable automated control and remote monitoring. This enhances overall efficiency.

Applications of Intelligent Conductivity Sensors

- Water and Wastewater Treatment – Ensuring regulatory compliance and optimal purification processes.

- Food and Beverage Industry – Monitoring process water, cleaning solutions, and product quality.

- Pharmaceuticals – Maintaining stringent water purity levels for drug production.

- Chemical Processing – Controlling the concentration of chemical solutions.

- Power Plants – Monitoring boiler feedwater and cooling water conductivity to prevent scaling and corrosion.

Why Upgrade to an Intelligent Conductivity Sensor?

Traditional conductivity sensors may still get the job done. However, the shift toward automation and digitalization makes intelligent sensors a smart investment. With features like real-time data access, remote calibration, and predictive maintenance, industries can improve efficiency. Moreover, they can reduce operational costs and ensure compliance with regulatory standards.

At Infinity Insight Management, we specialise in providing cutting-edge flow and water quality monitoring solutions tailored to your industry’s needs. Our range of intelligent conductivity sensors offers reliability, accuracy, and seamless integration into modern industrial systems.