How Vortex Gas Flow Meters Work: A Comprehensive Guide

⬅ Back to Posts

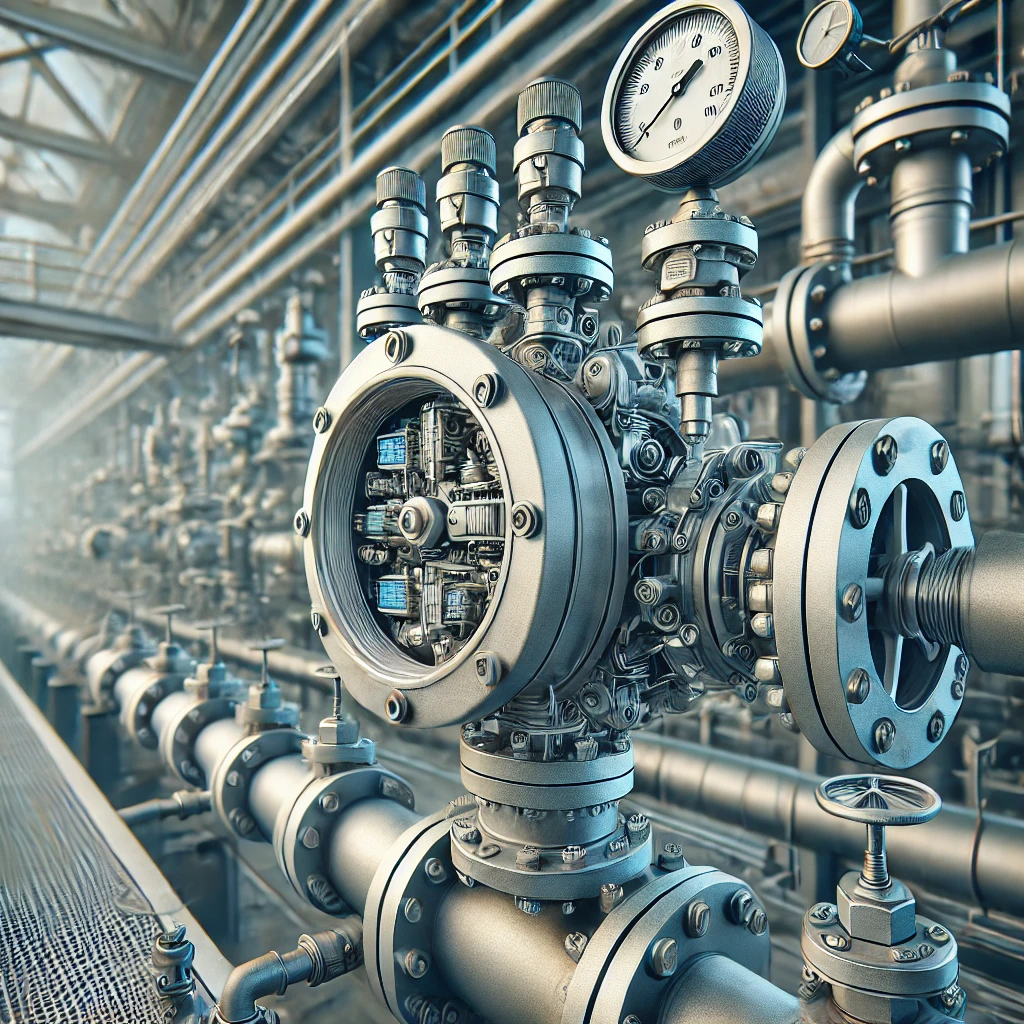

Vortex flow meters are widely used in various industries for measuring the flow of gases, steam, and liquids. They are especially popular in gas flow measurement due to their high accuracy, durability, and relatively low maintenance requirements. This post delves into how vortex gas flow meters function, what makes them unique, and why they are an excellent choice for gas flow applications.

Understanding the Basics of Vortex Flow Measurement

The principle behind vortex flow measurement is the vortex shedding phenomenon. When a fluid flows past a bluff body (a non-streamlined obstruction), it creates alternating low-pressure zones on either side of the body, leading to the formation of vortices. These vortices form and detach in a periodic pattern as the fluid flows, creating a series of oscillating vortices, also known as a Kármán vortex street.

The frequency at which these vortices are shed is directly proportional to the flow rate of the fluid. In other words, the faster the gas flows, the higher the frequency of vortex shedding. By detecting and measuring this frequency, a vortex flow meter can determine the gas flow rate.

Components of a Vortex Gas Flow Meter

- Bluff Body: The bluff body is the primary component responsible for creating the vortices. It is typically a solid, non-streamlined shape positioned in the center of the flow path. The size, shape, and positioning of the bluff body are carefully designed to generate stable, measurable vortices over a wide range of flow rates.

- Sensor: A sensor located downstream of the bluff body detects the vortices created by the flow. Different sensors can be used for vortex detection, such as piezoelectric sensors or thermal sensors, which are highly sensitive to the pressure changes caused by each vortex. When a vortex passes, it exerts a small force or temperature change on the sensor, allowing it to capture the frequency of the vortices accurately.

- Transmitter: The transmitter receives the frequency data from the sensor and converts it into a readable flow rate, often displayed in standard units such as cubic meters per hour or liters per minute. Modern vortex meters can also output data to control systems, providing real-time monitoring and control of gas flow in industrial applications.

How a Vortex Gas Flow Meter Works

Here's a step-by-step overview of the process:

- Flow Initiation: Gas flows through the pipeline and encounters the bluff body within the vortex meter.

- Vortex Shedding: As the gas flows around the bluff body, alternating vortices are created. These vortices shed at a frequency proportional to the flow rate of the gas.

- Frequency Detection: The sensor detects the vortices as they pass, registering each vortex and capturing the frequency of vortex shedding.

- Data Processing: The detected frequency is relayed to the transmitter, which uses the known proportional relationship between vortex shedding frequency and flow velocity to calculate the gas flow rate.

- Output and Display: The calculated flow rate is displayed or transmitted to a control system, allowing operators to monitor the gas flow in real time.

Advantages of Vortex Gas Flow Meters

- High Accuracy: Vortex flow meters are known for their accuracy, especially at higher flow rates. They can provide precise flow measurements even in challenging conditions.

- Low Maintenance: With no moving parts, vortex meters are highly durable and require minimal maintenance. This makes them cost-effective over time, particularly in high-pressure applications.

- Versatile: These meters can handle a wide range of fluids, including gas, steam, and liquid, though they are most effective with gases and steam.

- Wide Range of Applications: From HVAC and natural gas distribution to chemical processing and power generation, vortex flow meters are suitable for a variety of industrial and commercial gas flow applications.

Limitations of Vortex Gas Flow Meters

While vortex gas flow meters offer many advantages, they are not without limitations:

- Sensitivity to Low Flow Rates: Vortex meters may struggle to accurately measure very low flow rates, as the frequency of vortex shedding becomes difficult to detect at slower speeds.

- Noise and Vibration Interference: In some cases, external vibrations or noise in the pipeline can interfere with the sensor’s ability to accurately detect vortices, leading to measurement errors.

- Pressure Drop: The presence of the bluff body creates a minor obstruction, which can cause a small pressure drop in the pipeline. This is usually minimal but can be a concern in systems with low operating pressure.

Applications of Vortex Gas Flow Meters

The unique properties of vortex flow meters make them ideal for a range of applications, including:

- Natural Gas Flow Measurement: In natural gas distribution, accurate flow measurement is essential for billing and regulatory compliance.

- HVAC and Building Automation: In HVAC systems, vortex flow meters help monitor gas and steam flow to ensure efficient operation.

- Steam Flow Monitoring: The high temperature and pressure resilience of vortex meters make them well-suited for steam flow measurement in industrial plants.

- Chemical and Petrochemical Processing: Vortex meters can handle the demanding conditions of chemical plants, providing accurate and reliable measurements for process control.

Vortex gas flow meters are an effective and reliable solution for measuring gas flow in a variety of industrial and commercial applications. Their accuracy, durability, and low-maintenance design make them a preferred choice in environments where precision and reliability are critical. Whether for HVAC systems, natural gas distribution, or industrial process control, vortex flow meters provide the accuracy and performance needed to ensure efficient and safe operations.