Thermal Mass Flow Meters: A Comprehensive Guide

⬅ Back to Posts

Thermal mass flow meters are a popular and reliable choice for measuring the flow of gases in various industrial applications. Known for their accuracy, ease of use, and low maintenance requirements, these meters play a crucial role in industries such as oil and gas, chemical processing, pharmaceuticals, and environmental monitoring. In this blog post, we’ll explore what thermal mass flow meters are, how they work, their advantages, and their typical applications.

What is a Thermal Mass Flow Meter?

A thermal mass flow meter measures the mass flow rate of gases, rather than the volume of gas. This is especially useful because mass flow is independent of changes in temperature and pressure, making thermal mass flow meters highly accurate and versatile across different conditions. Unlike other flow meters that require compensation for variations in temperature or pressure, thermal mass flow meters calculate flow directly using the thermal properties of the gas.

How Does a Thermal Mass Flow Meter Work?

The operating principle of a thermal mass flow meter is based on heat transfer. Here’s a simplified explanation of how they function:

- Two Sensors: Most thermal mass flow meters contain two sensors—a heated sensor and a temperature sensor. The heated sensor raises the temperature of the gas flowing through the meter, while the second sensor measures the temperature of the gas downstream.

- Heat Dissipation: As the gas flows past the heated sensor, it carries some of the heat away, cooling the sensor down. The amount of heat carried away is proportional to the mass flow rate of the gas.

- Temperature Difference: The temperature difference between the heated sensor and the ambient temperature sensor provides a direct measurement of the mass flow. The greater the flow, the more heat is dissipated, and the more the sensors need to compensate by adjusting the heating current.

- Real-Time Monitoring: The meter continuously measures the amount of energy required to maintain the temperature difference, allowing it to calculate the mass flow rate in real-time.

Types of Thermal Mass Flow Meters

There are two primary types of thermal mass flow meters:

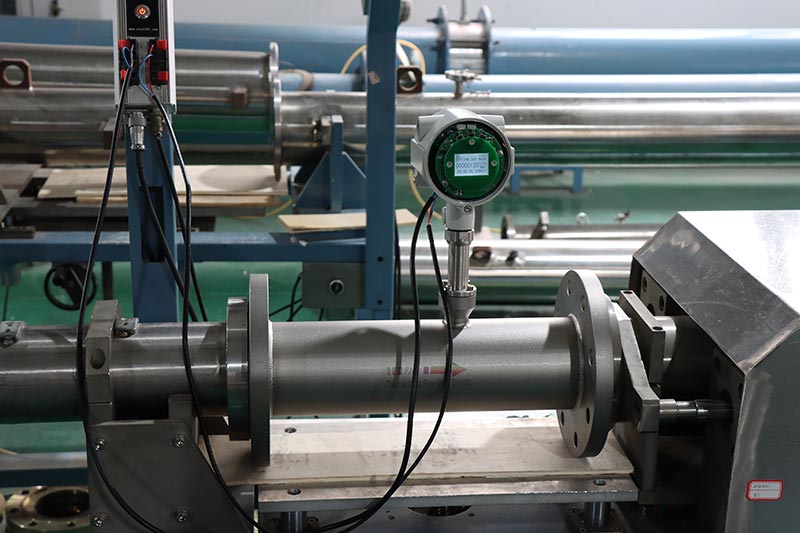

- Insertion Type: These meters are typically installed in large pipelines or ducts, where the sensing element is inserted directly into the flow stream. They are ideal for measuring flow in larger pipes.

- Inline Type: These are used for smaller pipes or when high precision is required. Inline thermal mass flow meters have the sensors built into a section of piping, allowing them to measure flow more accurately in smaller applications.

Advantages of Thermal Mass Flow Meters

Thermal mass flow meters offer several key advantages that make them a preferred choice for many applications:

- No Moving Parts: One of the biggest advantages of thermal mass flow meters is that they have no moving parts. This reduces wear and tear, making them highly reliable and requiring minimal maintenance.

- Direct Mass Flow Measurement: Unlike volumetric flow meters that need temperature and pressure compensation, thermal mass flow meters directly measure the mass flow of gases, making them more accurate and efficient.

- Wide Range of Applications: They are highly versatile and can be used for a wide range of gases, including air, natural gas, carbon dioxide, nitrogen, and many more.

- Low Pressure Drop: Because these meters don’t have any restrictions or mechanical components that block the flow, they create little to no pressure drop, making them energy-efficient.

- Easy Installation and Integration: Thermal mass flow meters are easy to install and can be integrated into existing systems without significant modifications. Their compact design allows for installation in tight spaces.

Typical Applications

Thermal mass flow meters are particularly useful in applications that require precise gas flow measurements. Some common industries and applications include:

- Environmental Monitoring: These meters are often used in stack gas monitoring to measure emissions and help industries stay compliant with environmental regulations.

- Compressed Air Systems: In manufacturing plants, thermal mass flow meters are used to monitor the consumption of compressed air, ensuring efficient usage and detecting leaks in the system.

- Biotechnology and Pharmaceuticals: In processes where accurate gas measurements are critical, such as in fermenters or bioreactors, thermal mass flow meters provide precise control over gas flows.

- Oil & Gas Industry: They are used in flare gas measurement, natural gas processing, and in various other applications where accurate gas flow measurement is crucial.

Conclusion

Thermal mass flow meters are indispensable tools for measuring gas flow accurately and efficiently across a range of industrial applications. Their ability to directly measure mass flow, along with their durability and low maintenance requirements, makes them a highly sought-after solution in industries that depend on precise gas flow data. Whether in environmental monitoring, chemical processing, or compressed air management, thermal mass flow meters provide the reliability and accuracy needed for optimal system performance.

If you’re considering implementing a thermal mass flow meter in your application, it’s essential to choose a meter suited to your specific gas type, flow range, and installation environment. With the right meter, you’ll enjoy greater accuracy, improved operational efficiency, and peace of mind.